Sufon Seals offers a comprehensive range of mechanical sealing

solutions designed to cater to the

unique requirements of different industries.

Conical Coil Spring Mechanical Seal looking from Sliding Face of the Rotating Seal Ring is designed as Right Hand Shaft Rotation which needs Right Hand Spring and Vice Versa.

These Seals are Cost Effective Seals for Basic Application Equipment such as Centrifugal Pump and other Equipment with Rotating Shaft, Handling Water, Oils, Fuels, Mild Chemicals and Liquids Containing of Low Quantity of Abrasive. We are the manufacturer of Conical Coil Spring Mechanical Seal, Pusher Mechanical Seals in Mumbai INDIA.

The Seal with Single Spring design and is depended on the Shaft Rotation. Looking from Sliding Face of the Rotating Seal Ring is

designed as right hand Spring for Shaft Rotation and vice-versa. Seal is designed as Torque Transmission from Drive Collar to Spring and Seal Ring. These Seals is cost effective for Basic Application Equipment such as Centrifugal Pump and other Equipment with Rotating Shaft, Handling Crystallizing Slurry, Suspended Solid Slurry, Saturated Chemical Slurry and General Chemical Slurry.

This Seal is recommended for clean media application. We are among top manufactures of Multi Spring Mechanical Seal. PTFE Wedge

Construction of the Secondary Sealing Member provides Universal Service application. Construction of these Seal designs hold whole Rotary Parts together with the help of Snap Ring which is installation and removal is make easiest. These Type of Seal designed and used for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal Pumps and other Equipment with Rotating Shafts.

This Seal Single Spring Mechanical Seal are designed and manufactured to meet all the requirements and most suitable for this

applications. These seal are Internally Mounted Unbalanced design which Seal having 'O' Ring as a Secondary Sealing member and other Seal having PTFE Wedge as a Secondary Sealing member. Secondary Sealing member can be changed as per Chemical Compatibility. The Helical Coil Spring designed Seal help to Seal the Dirty and Clogging type of application. Construction of these Seals designs hold whole Rotary Parts together with the help of Snap Rings which is make easiest for Installation and Removal.

Seal is recommended for clean media application. PTFE Wedge Construction of the Secondary Sealing Member provides Universal

service application. Construction of these Seal designs holds whole Rotary Parts together with the help of Snap Rings which is make easiest of Installation and Removal. These Type of Seal designed and used for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts. Multi Spring Unbalanced Mechanical Seal are carefully designed

It is Externally Mounted Reverse Balance design Seal which having 'O' Ring as a Secondary Sealing member. Secondary Sealing member can be changed as per Chemical

Compatibility. All Metal Components including spring are Isolated from Aggressive media Sealing. Simplicity in Checkout Function and Cleaning Possibility as this Mechanical Seal located easily access outside the pump. The Single Design Seal can be installing as Dual Back to Back Arrangement and can operate on Low Barrier Fluid Pressure due to its Reverse Balance Design feature. We are the top manufacturer of Reverse Balance Multi Spring Seal.

This is single wave spring seals for most general application, being used in industries like Paper and Pulp, Sugars, Sewage, Polymer, Rubber etc. Its compact design with reduced

axial length is the major advantage of using single wave spring seals. These seal are designed to handle dirty and slurry application as spring clogging does not occur.

It is a Compact Single Spring Rubber Bellow Mechanical Seals for universal general purpose for Water / Water Based Solution like Oils,

Fuels and Other Fluids and even with some Content with Abrasive and for a very wide operating condition designed for Centrifugal Pump. Rotary Equipment and Industrial applications (Food Processing, Water System, Waste Water Treatment for Petrochemical Processing, Pulp and Paper)

PTFE Mechanical Seals are Specially Designed for using Extremely Corrosive Duties. All Metal Components are including springs are Isolated

from the Sealed, Aggressive Medium. These Seal Design Faces are molded with Glass Filled PTFE with Highly Flexible PTFE Bellow. Simple checkout method function and cleaning possibility as this Mechanical Seal located easily accessible outside the pump.

Metal Bellow mechanical seals are destined for petrochemical, chemical, pharmaceutical and food processing industry, for process pumps and other equipment with rotating shaft.

Rotating bellows design acts to clear convolutions and prevent accumulation of debris. These bellow seals are constructed by welding a series of diaphragms together at the edges to form a bellows unit. Recommended for high temperature mediums e.g. hot oils, pitch, tar and other hydrocarbons, fuels, liquid gases and other mediums with low content of abrasives.

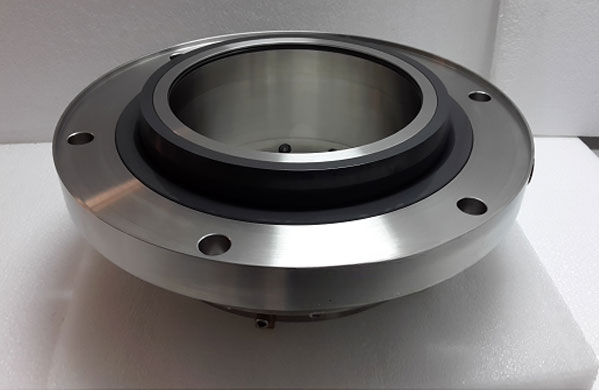

Single Cartridge Balance seal are Recommended for Clean media application. This seal is Standard for using where Corrosive

Liquid are being Processed. Construction of these Seal designs holds whole Rotary Parts together with the help of Snap Rings which is make easiest for Installation and Removal. This Type of Seals is designed for using for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts.

This seals are single acting pre-assembled cartridge mechanical seals, which could be directly installed without any dimensional

adjustment during installation. These cartridge unbalanced seals are independent of direction of rotation being designed to handle slurries, sludge, thick syrup and polymerising fluids. The spring provided in the cartridge construction are being isolated from the fluid enhancing the seal life.

Double Cartridge balance Seal are Recommended for Clean and dirty media application . Seal can tolerate reversal

pressure. Double Cartridge balance Seal is Standard for using where Corrosive Liquid are being Processed. We are the top manufacturer of Double Cartridge Seal Type ZR600/D in mumbai, INDIA This Type of Seals is designed for using for Petroleum Products, Low Aggressive Chemicals and Refrigerants in Centrifugal pumps and other Equipment with Rotating Shafts.

This seals double acting cartridge mechanical seals having integral sleeve and gland plate. These multi spring design seal are pre-

assembled, which could be directly installed without any dimensional adjustment during installation. These seals are unbalanced, independent of direction of rotation.

This Seal is high pressure and high speed cartridge designed for high pressure applications, like hot water, crude oil,

light hydrocarbons. These seal are provided with single, double or tandem arrangement, which are widely used for applications such as boiler feed water pumps, main crude oil transportation pump and multi-phase pumps. Its sturdy designed and drive arrangement makes the seal suitable for high pressure applications. Multiple spring designed provides uniform face loading.

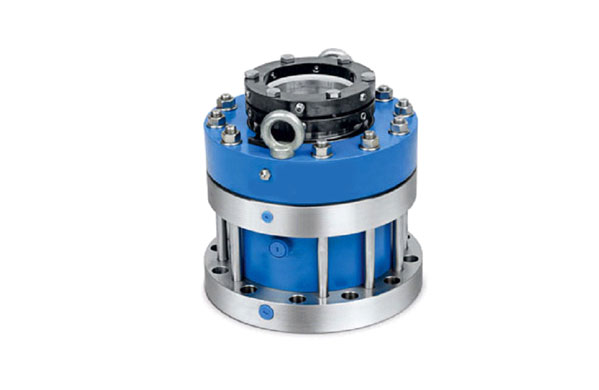

Dry Running Agitator Seals are designed for Top, Bottom and Side Entry Drives in Agitators, Mixers OR Blenders in case when Non-

Aggressive and Non-Hazardous Media are sealed with the use of Cooling Liquid Preventing against Dry Running. Construction of MOC designed of these Seals purpose of holding whole Rotary Parts together with the help of Snap Rings which make easy for Installation and Removal.

Single Agitator Mechanical Seals are designed for Top, Bottom and Side Entry Drives in Agitators, Mixers OR Blenders and where

Non-Aggressive and Non-Hazardous Media are Sealed with the use of Cooling Liquid preventing against Dry Running. Construction of MOC designed of these Seals purpose of holding whole Rotary Parts together with the help of Snap Rings which eases while Installation and Removal of Seals.

Double Agitator Mechanical Seals are designed for Top, Side and Bottom Entry Drives in Agitators and Reactors with balance and

unbalance configuration. Compact Economical Cartridge Double Mechanical Seal for Agitators and Reactors. Seal Design Incorporate with location of Bearings very close to the Seal. These Seal specially designed for any mixed and pressurized liquid in Vessel with Top Entry Agitators where no leakage in Process Gas OR Fluids to the Environment can be tolerated. Complete Pre-assembled Tested Unit ready for installation. These Seal are used for Exclusive Solid Seal Faces, Stationary Seats, thus Lowest Level of Seal Face distortion when Expose to Compressive Load and Thermal Pressure.

In Dry gas or gas lubricated agitator seal grooves are machined into the mating ring faces. Then pressurized gas is injected

between the seals. As the shaft rotates, gas flows into the tip of the groove and which in return distances the faces creating thin film of gas for small amount ranging in micron. thus separating the faces. This seal continues to operate, even if barrier gas pressure is momentarily lost, maintaining the gas film between the barrier gas and the process.

Mechanical seal designed is a unique seal developed to meet stringent technical requirements of Boiler feed water pumps. Rotating stationary ring design makes it

suitable for high speed application & avoids critical requirement of stuffing box face squareness. Both the faces are having strong positive drive & locking arrangement which make seal very strong and sturdy. Thermodynamic circulation grooves inscribed on the rotating faces boost the cooling of the sliding faces by reducing the coefficient of friction and protecting the seal against thermal over loading. Increased coolant flow effected by the pumping screw & the fluid guiding channel combine to force the cold water into the gap between dynamic ring & stationary ring, blowing out gas bubbles and dirt particles & picking up frictional heat. In view of risk dynamic distortion because of high sliding velocity of over 25 m/sec the springs are located in the stationary part.

This seal is developed & equivalent to an original Grundfos seal. This seal is designed with single spring & o-ring with cartridge arrangement. These seals have threaded

hex head which is easy to install in Grundfos make CR, CRN, and CRI series pumps, this seal is comfortable to used in wide range of application.

We are quite reputed among the manufacturers and exporters of Mechanical Seals for Textile Industry in India and various countries. The use of optimum quality

materials in the manufacturing of the textile mechanical seals ensures high durability, waterproof, corrosion & abrasion resistance and auto resistance to climatic variations. Additionally, customers are eased with the availability of the textile seals that comply with the international quality standards.

The split seal is perfect for equipment that is complicated and time consuming to disassemble such as large pumps, vertical pumps and horizontal split case pumps.

This confirmed compact design can be used in a large variety of equipment and process materials. Several pumps types lend themselves towards the application of radically divided or “split” seals. Large vertical pumps, close-coupled horizontal pumps, and further equipment, which require extensive disassembly to vary the mechanical seal, are all good candidates for mechanically split seal. Compression packing & the related routine maintenance can be eliminated.

We are looked upon as one of the renowned food industry seals Manufacturer in India. The unmatched quality and unsurpassable performance has concerned customers from

all round the globe to place bulk orders. The use of optimum quality materials in the manufacturing ensures high durability, tensile strength and resistivity to adverse conditions. Moreover, the Mechanical food industry seals offered by us are ideally designed to meet the applications.

We provide unique designs that gives excellent results in all light to medium slurry. This seals satisfy the demand for advanced and reliable sealing solutions on even the heaviest of

slurry applications typically found in mining applications.We made up of high quality packing with superior sealing capabilities. This sealing concept meets the increased sealing demands from our customers.

We are engaged in offering our clients a wide range of Kirloskar Pump Seal which are also available as per client specification. These are available in single and multi spring types,

these mechanical seals are designed using optimum quality raw material and leading techniques.

We offer a wide range of precision engineered custom KSB Pump Seals which is available in single and multi spring types, these mechanical seals are designed using optimum

quality raw material and leading techniques. Moreover, our mechanical seals undergo various tests under the direction of quality controllers, in order to assure its flawlessness.

Being a prominent firm, we are engaged in manufacturing and supplying a distinct assortment of Flowserve Pump Mechanical Seals which is used in a wide variety of

applications, our entire range of cartridge and semi cartridge seal is manufactured, keeping in mind the quality norms using optimum quality steel and leading techniques. We are giving this seal to our customers within a given time frame with numerous stipulations.

We Provide superior quality Johnson Pump Seal Johnson Pump Seal which are mostly used in industrial Application. We offer this pump seal to our customers after checking it

properly. Our customers can avail this pump seal at reasonable price.

We stocks and supplies a full range of Alfa Laval mechanical seals. Optimizing the latest technology, we manufacture a range of Alfa Laval Pump mechanical seals. If you have

a requirement for a Alfa Laval mechanical seal, then please don't hesitate to contact us and we will endeavour to respond to your enquiry within 8 hours.

We bring forth AKAY Pump Mechanical Seal that are designed for AKAY Pump models like CHP-S, CHP-ST, CHP-M, CHP-MT and CHP-SCP. AKAY Pump Mechanical Seal can also be

designed as per the specifications laid by the customers. They are available in MOC SS. In addition to this, we assure to provide quick and safe delivery of AKAY Pump Mechanical Seal at the customer’s location.

We supply Mechanical Seal for MATHER and PLATT pumps (now known as Wilo pumps). MATHER and PLATT Pumps (Wilo) mechanical

seals are available for the following MATHER & PLATT Pump models: BST, AST, CST, Etiso, Pniso, BSN etc. Mather & platt pump mechanical seals are available in MOC as requested like SS304, SS316, SS316l. We also manufactured as per client's sample or drawing. We offer high quality Wilo/ MATHER and PLATT pump mechanical seals that are manufactured using latest production techniques. We are recogonised as one of the leading pump mechanical seal supplier from india.

With the help of our diligent professionals, we are offering a complete range of Microfinish Pump Mechanical Seal. These products are made of stainless steel and are offered

in a variety of makes. Owing to their robust and sturdy construction, high tensile strength and easy installation, these products are extensively used in a wide variety of applications.

We are instrumental in offering superior quality Grundfos Pump Cartridge Seals These Grundfos Seals have sophisticated design for rough slurries. Grandfos pump seal used for

stainless steel vertical multistage centrifugal pump.It is suitable to grundfos pump CR(N) 32, 45, 64, 90, 150 Multi spring Seal for Grudfos Hilge® pumps.

We offer high quality range of Investa Pump Mechanical Seals, which confirm to the highest standards of quality. Our Investa Pump Mechanical Seals are known for their

superior quality, durability and optimum performance. Manufactured from quality raw material these are in high demand by our client’s spread across the nation. We also meet customized requirement for our clients benefit.